Considering Painting Galvanized Steel to finish off exposed garage door beams or lintels and match your home's color scheme? Unfortunately, the process of Painting Galvanized Steel poses a challenge. That's because the layer of zinc on the metal, which is specifically designed for corrosion reduction, also rejects paint, resulting in peeling and shedding.

This implies that if Painting Galvanized Steel is not executed properly, vital steel components like lintels or garage door beams, which are exposed at the bottom, will require painting. Neglecting this step can lead to troublesome maintenance issues in the future. So, how can you ensure proper painting of galvanized steel to avoid these pesky issues down the track?

Read More: What is Galvanized Steel? The Galvanized Steel Manufacturing Process

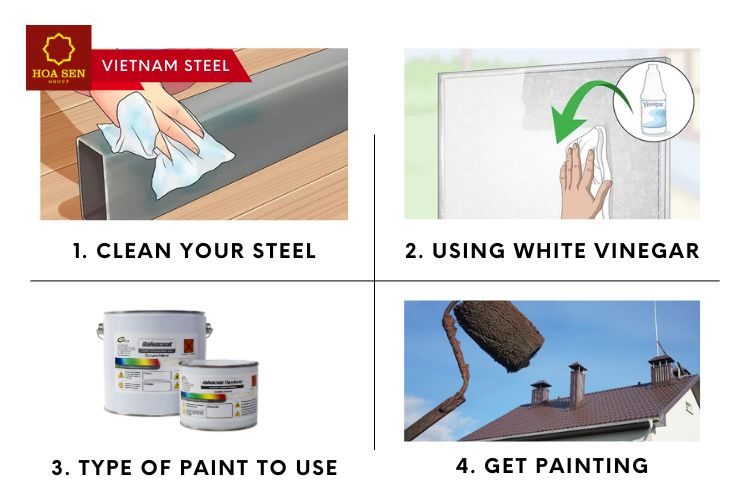

Steps To Painting Galvanised Steel

1. Preparing The Surface Of Painting Galvanized Steel

The first step in the process of Painting Galvanized Steel is to thoroughly clean the surface. Take a rag and remove any oils, dirt, dust, salts, corrosion products, brittle material, soluble salts, and other contaminants that may affect the texture. It is essential to have a smooth surface for painting, as it makes the process much easier and more enjoyable.

2. Utilizing White Vinegar For Painting Galvanized Steel

After ensuring that your galvanized steel is clean, it's time to introduce a household product that works wonders in promoting paint adhesion: white vinegar. White vinegar is a safe and non-toxic alternative to industrial solvents. Apply white vinegar to a clean rag and thoroughly wipe each surface to eliminate any residue.

Read More: Does Galvanized Steel Rust Over Time?

3. Selecting The Appropriate Paint For Galvanized Steel

While you may have already chosen your paint, it is crucial to consult with your local paint supplier to ensure you have the best product for Painting Galvanized Steel. Different factors such as weather conditions, humidity, geographical location, and exposure to elements can impact the choice of paint.

If you intend to use acrylic latex paint, it is important to use a primer as this type of paint is not designed for galvanized steel. However, if you prefer to skip the primer phase, opt for paint types that adhere well to steel. Avoid using alkyd-based paints or oil-based primers when painting galvanized steel.

Can you spray paint galvanized steel? Spray paint can be used for Painting Galvanized Steel, provided that the surface has been appropriately primed.

4. Get Painting

You heard us. Get painting! Having followed all these steps, you’ll be left with a smooth surface that is easy to paint.

Achieving Optimal Surface Pre-Treatment for Galvanized Steel

When it comes to Painting Galvanized Steel, there are four recognized methods for achieving optimal surface pre-treatment. These methods include T-Wash, Etch primers, sweep/whip blasting, and weathering. Each technique serves the purpose of creating a solid substrate for painting.

1. T-Wash

Considered the most effective pre-treatment method, T-Wash utilizes a modified zinc phosphate solution with traces of copper salts. This solution reacts with the galvanized steel surface, resulting in a dark grey or black discoloration. Once dry, a T-Washed surface can be left for 30 days before proceeding with painting Galvanized Steel.

2. Etch Primers

Etch primers are suitable for older and weathered galvanized steel. This method provides a means of surface pre-treatment for Painting Galvanized Steel.

3. Sweep/Whip Blasting

Sweep/whip blasting involves mechanically blasting the galvanized steel at 40psi (2.7 bar) using fine copper slag, J blast, or carborundum powder. This process creates an "etch profile" on the surface, which offers a microscopic texture for the paint to adhere to.

Sweep/whip blasting minimizes maintenance issues and prevents peeling in the future. It is crucial to use a finer material to avoid damaging the galvanizing and exposing raw steel.

4. Weathering

Weathering is a natural process that takes at least six months to fully activate. To begin, surface contaminants are removed using abrasive pads or brushes to prevent the restoration of the zinc surface.

After scrubbing, the surface undergoes a hot detergent wash and is rinsed with clean water. Once dry, Painting Galvanized Steel can commence. It is important to avoid weathering in marine environments with high chloride levels.

By utilizing these professional surface pre-treatment methods, you can ensure an optimal substrate for Painting Galvanized Steel, resulting in a long-lasting and visually appealing finish.

Read More: Safely Welding Galvanized Steel: A Step-by-Step Guide

Vietnam Steel by Hoa Sen Group