"How to Cut Galvanized Steel Wire" is a comprehensive guide that provides valuable insights and step-by-step instructions on effectively cutting galvanized steel wire. Galvanized steel wire is known for its durability and resistance to corrosion, making it a popular choice in various industries and applications.

This guide explores different cutting methods, such as using wire cutters, angle grinders, and power shears, while highlighting safety precautions and offering useful tips for achieving precise and clean cuts. Whether you're a DIY enthusiast or a professional, "How to Cut Galvanized Steel Wire" equips you with the knowledge and techniques necessary to tackle your cutting projects with confidence.

What is Galvanized Steel Wire?

Galvanized steel wire is a type of wire that has been coated with a layer of zinc to enhance its durability and resistance to corrosion. The process of galvanization involves immersing the steel wire in a bath of molten zinc or applying a zinc coating through electroplating.

The zinc coating acts as a protective barrier, preventing the underlying steel wire from coming into direct contact with moisture, oxygen, and other elements that can cause corrosion. This makes galvanized steel wire suitable for a wide range of applications, including fencing, construction, electrical wiring, and agricultural uses.

It is valued for its strength, longevity, and ability to withstand harsh environmental conditions. Galvanized steel wire is available in various thicknesses and forms, such as galvanized steel rope and galvanized steel mesh, providing versatility for different projects and requirements.

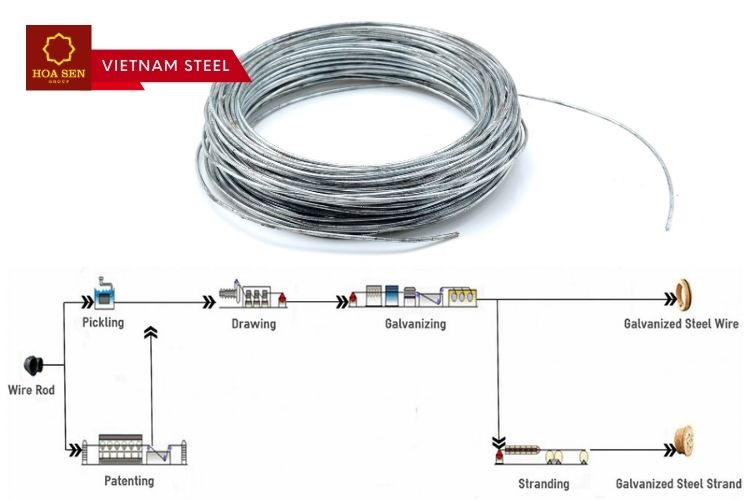

Galvanized Steel Wire manufacturing process

The production of galvanized steel wire involves several key steps. It begins with wire rods, which are raw materials used to make the wire. These wire rods undergo a pickling process that includes annealing, rust removal, and acid washing. Annealing involves heating the wire rods to a specific temperature and then slowly cooling them, which helps to improve their ductility and reduce internal stresses. Rust removal and acid washing are carried out to eliminate any impurities or surface contaminants present on the wire rods.

Once the wire rods have been pickled, they are ready for the wire drawing process. In this step, the wire rods are passed through a series of dies in a wire drawing machine. The dies gradually reduce the diameter of the wire, transforming it into the desired size and shape. This drawing process helps to improve the wire's tensile strength and uniformity.

After the wire drawing process, the wire is ready for galvanization. There are two main methods of galvanizing: hot-dipped galvanization and electro galvanization. In the hot-dipped galvanization method, the wire is immersed in a bath of molten zinc. The zinc bonds with the surface of the wire, forming a protective layer that guards against corrosion. Electro galvanization, on the other hand, involves the use of an electrolytic process to deposit a layer of zinc onto the wire. This method offers more precise control over the thickness of the zinc coating.

Following the galvanizing process, the galvanized steel wire is typically subjected to stranding. This involves twisting multiple strands of wire together to create a stronger, more durable product. The stranding process is commonly used for applications that require higher tensile strength, such as overhead power lines or structural cables.

Finally, the galvanized steel wire is rolled into coils for sale. These coils are convenient for storage, transportation, and subsequent processing by end-users. The galvanized steel wire's resistance to corrosion, enhanced by the zinc coating, makes it a versatile and reliable material for various applications, including fencing, construction, electrical wiring, and agricultural uses.

What Are the Common Uses of Galvanized Steel Wire?

Galvanized Steel Wire offers a multitude of benefits, including exceptional corrosion resistance, durability, high tensile strength, and a smooth, shiny surface. These qualities make it highly sought-after and widely used in various applications.

- Binding Materials: Galvanized steel wire's strength and durability make it a preferred choice for binding, baling, or earthing materials on construction sites. Its weather resistance makes it popular among builders, and it is often utilized to create gabions for erosion control.

- Protective Fencing: With its robustness, galvanized steel wire is commonly employed in fencing or enclosures around residential or commercial properties, safeguarding them from intruders or animals. Its corrosion resistance makes it suitable for outdoor use, and it can be found around schools, sports fields, and other areas requiring security.

- Handicrafts: The bright and glossy surface resulting from the galvanizing process makes Galvanized Steel Wire ideal for crafting household items like bookshelves, vase holders, storage baskets, and other decorative pieces.

- Agricultural Uses: Galvanized Steel Wire plays a crucial role in orchards, supporting the growth of grapes, tomatoes, and other crops. Its zinc coating enables it to withstand exposure to pesticides and other agricultural chemicals.

- Daily Applications: Galvanized Steel Wire finds diverse everyday uses, such as packaging materials, construction of animal cages, hanging pictures or paintings, and other practical purposes.

In summary, the versatility of Galvanized Steel Wire makes it an indispensable material across industries, providing strength, protection, and aesthetic appeal. Whether used in construction, fencing, handicrafts, agriculture, or everyday items, Galvanized Steel Wire continues to prove its worth as a reliable and durable solution.

Can Galvanized Steel Wire rust?

Is Galvanized Steel Wire Susceptible to Rusting? The answer is yes, albeit at a significantly slower rate. Like any steel product, Galvanized Steel Wire can oxidize and eventually rust when exposed to rain or moisture. Rust not only affects the appearance of the wire but also compromises its longevity.

However, the process of galvanizing provides an added layer of protection by coating the wire with zinc, enhancing its resistance to corrosion and rust formation. As a result, Galvanized Steel Wire, particularly hot-dipped galvanized steel wires, experiences a significantly reduced rate of rusting, allowing for prolonged durability and performance.

Read More: Galvanized Steel vs Stainless Steel: What's the Difference?

How to Cut Galvanized Steel Wire

Galvanized steel wire, also known as steel wire with a hot-dipped zinc coating, possesses remarkable resistance to rusting, which significantly extends its lifespan. Interestingly, despite the protective coating, cutting galvanized steel wire remains a straightforward task. Knowing how to cut galvanized steel wire is essential for various applications.

The method of cutting galvanized steel wire depends on the wire's thickness, with wire-cutting diagonal shears being suitable for wires thicker than 18 AWG, and diagonal shears or the cutting edge of needle-nose pliers being suitable for smaller-diameter wires measuring 18 AWG or thinner.

- To begin the cutting process, ensure that the jaws of the diagonal shears or needle-nose pliers are open. Using a measuring tape, accurately measure and determine the desired length of the galvanized steel wire, marking it with a permanent marker or a felt-tip pen. This marked point will serve as a guide for the cut.

- Next, place the section of the galvanized steel wire that needs to be cut into the open jaws of the diagonal shears or position it onto the cutting edge of the needle-nose pliers, aligning it with the marked point. It is essential to ensure a secure grip on the galvanized steel wire to maintain control during the cutting process.

- With a firm grip on the tool, apply steady and even pressure to the handles of the diagonal shears or needle-nose pliers. Continuing with the steps of "How to Cut Galvanized Steel Wire," squeeze the handles until the blades or cutting edge have completely severed the galvanized steel wire. Take caution while cutting to avoid injury and ensure a clean and precise cut.

By following the steps of "How to Cut Galvanized Steel Wire" and exercising care, cutting galvanized steel wire can be accomplished effectively and efficiently, allowing for various applications in construction, DIY projects, wiring installations, and more. Mastering the techniques of "How to Cut Galvanized Steel Wire" empowers individuals to handle this durable material with ease and precision.

Read More: What is Galvanized Steel? The Galvanized Steel Manufacturing Process

Vietnam Steel by Hoa Sen Group