What is Carbon Steel?

In the realm of steel, the misconception that all varieties are identical holds no ground. Contrary to this notion, steel represents an alloy metal predominantly composed of iron and carbon, along with other trace elements. Boasting exceptional tensile strength and cost-effectiveness in production, steel has emerged as a favored choice among manufacturing companies. Nevertheless, the world of steel encompasses diverse types, each distinguished by its exclusive traits. Notably, "Carbon Steel" stands out as a preferred option over its counterparts.

Carbon steel earns its distinction as a unique steel variant due to its higher carbon concentration, as the name aptly implies. While most steel types possess a relatively low carbon content ranging from about 0.05% to 0.3%, carbon steel sets itself apart with a remarkable carbon content of up to 2.5%. Though this may seem like a modest difference, this elevated carbon level brings forth a range of appealing advantages that are unparalleled in other steel varieties.

The American Iron and Steel Institute (AISI) defines carbon steel as follows:

- There is no minimum content stated chromium, cobalt, molybdenum, nickel, niobium, titanium, tungsten, vanadium, zirconium, or necessary for the addition of any other element to achieve the desired alloying effect.

- The copper minimum stated cannot exceed 0.40%.

- Or the maximum content indicated for any of the elements listed below does not exceed the percentages supplied: Manganese is 1.65%, silicon is 0.60%, and copper is 0.60%.

Carbon Steel Advantages

Opting for carbon steel over conventional steel offers numerous advantages, with increased strength standing as a key highlight. The infusion of carbon enhances the strength of iron, or steel, by rearranging its crystal lattice. While carbon steel can still experience stress and fractures under pressure, the likelihood of such occurrences is significantly reduced compared to other steel types. This exceptional attribute renders carbon steel highly effective in applications demanding robustness. Centuries ago, Japanese bladesmiths crafted swords from high-carbon tamahagane steel, exemplifying its prowess. In modern times, carbon steel finds extensive use in diverse applications, ranging from construction materials to tools, automotive components, and beyond.

- Strong and highly durable

- Higher strength

- Corrosion resistant properties

- High and low-temperature resistant

- It exists in a large variety of types

- Durable and reasonably inexpensive over the duration of its lifespan

- Environmentally friendly and recyclable

- Low maintenance and easily cleaned

- It can be applied to a particular finish if an attractive cosmetic appearance is desired and does not tarnish readily

Carbon Steel Disadvantages

While carbon steel boasts significant advantages, it is essential to acknowledge some of its drawbacks in comparison to traditional steel. Due to its remarkable strength, working with carbon steel presents challenges. Its resistance to easy bending and molding into various shapes can limit its utility in specific applications. Furthermore, carbon steel exhibits greater susceptibility to rust and corrosion when compared to other steel types. Unlike stainless steel, which contains added chromium (typically around 10% to 12%) that forms a protective barrier against moisture-induced rusting, carbon steel lacks chromium. Consequently, prolonged exposure to moisture may lead to rust formation in carbon steel products.

- More prone to rust and corrosion than other steel types

- Difficult to bend and mold into diverse shapes

- High cost, especially at the initial expense

- It can be tough to work with, especially without the most advanced machinery and methods.

- It can often result in costly waste and re-work

Read More: What is steel coil used for?

Types of Carbon Steel

1. Low-carbon Steel

0.05-0.25%, mild steel gains malleability and ductility, making it easily workable. Though low in tensile strength, its cost-effectiveness and ease of shaping make it a popular choice. Additionally, surface hardness can be enhanced through carburizing.

Another noteworthy subset of low-carbon steels is "High-Strength, Low-Alloy Steels" (HSLA), enriched with ingredients like copper, nickel, vanadium, and molybdenum, accounting for up to 10% of their composition. These HSLA steels boast heightened strength attributed to effective heat treatment, all while retaining their ductility, enabling seamless forming and machining. Remarkably, they also exhibit superior corrosion resistance compared to regular low-carbon steel, further expanding their utility. Embracing the versatility and advantageous properties of "Carbon Steel," including its various iterations like mild steel and HSLA, paves the way for optimal material choices across a myriad of applications.

2. Medium-carbon Steel

In the realm of steel, "Carbon Steel" showcases diverse variations, and "Medium-Carbon Steel" emerges as a notable contender. With a carbon content ranging from 0.30% to 0.50% and manganese levels between 0.60% to 1.65%, this steel type holds distinct mechanical properties that can be further enhanced through a specific heat treatment process. By undergoing austenitizing, followed by quenching and tempering, medium-carbon steel develops a martensitic microstructure, reinforcing its performance.

Though heat treatment is feasible only on exceptionally thin sections, there exists a solution to bolster steel's heat treatability. Additional alloying elements like chromium, molybdenum, and nickel can be incorporated to elevate its capacity for heat treatment and subsequent hardening.

As a result of the hardening process, medium-carbon steels attain superior strength compared to low-carbon steels, albeit with some trade-offs in terms of ductility and toughness. The primary applications for this steel variant lie in manufacturing machine components such as shafts, axles, gears, crankshafts, couplings, and forgings. Notably, medium-carbon steel may also find utility in rails and railway wheels, making it a versatile choice across various industrial sectors. Embracing the advantages of "Medium-Carbon Steel" and its potential for reinforcement through heat treatment unlocks a wide array of possibilities for sturdy and reliable engineering components.

3. High-carbon Steel

When it comes to steel, "Carbon Steel" takes on various forms, and "High-Carbon Steel" emerges as a remarkable contender, boasting a carbon content ranging from 0.60% to 1.00% and manganese levels between 0.30% to 0.90%. Among carbon steel types, high-carbon steel stands out with its unparalleled combination of hardness and toughness, though it exhibits relatively lower ductility. Due to their inherent hardness and toughness, high-carbon steels undergo hardening and tempering processes, making them exceptionally wear-resistant. In practical applications, these steels find great utility in crafting springs, rope wires, hammers, screwdrivers, and wrenches, ensuring long-lasting and robust performance.

Furthermore, high-carbon steels expand their versatility in the form of "Tool Steels" and "Die Steels," augmented with additional alloying elements like chromium, vanadium, molybdenum, and tungsten. The integration of these elements results in particularly resilient and wear-resistant steel, primarily due to the formation of carbide compounds such as tungsten carbide (WC). This amalgamation of elements enhances the steel's toughness and wear resistance, making it a preferred choice in the production of high-performance tools, dies, and industrial components.

Embracing the superior characteristics of "High-Carbon Steel" and its specialized counterparts, including tool steels and die steels, empowers industries to harness the utmost durability and performance from these exceptional steel variants. From toughened tools to wear-resistant components, high-carbon steel proves its mettle in a range of critical applications.

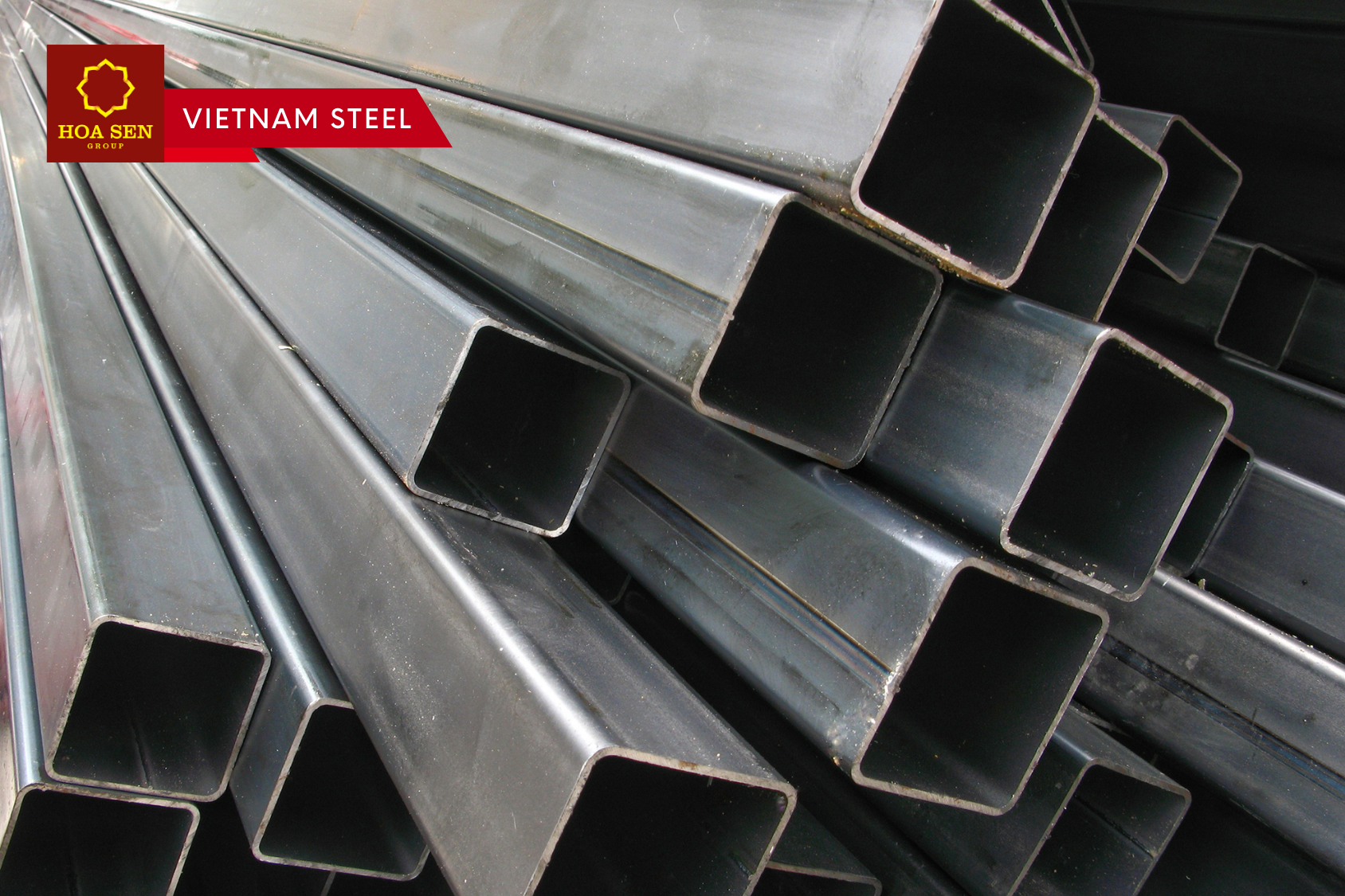

Types of Carbon Steel Products

1. Construction Structure Steels

Carbon steel, with its intermediate to high carbon contents and elevated levels of other alloying elements, boasts exceptional formability and structural integrity. This attribute allows for versatile shaping of carbon steel into an extensive array of steel profiles and sections, catering to various construction needs.

These steels undergo rigorous treatment and testing, adhering to a range of specifications to meet demanding building requirements. As a result, carbon steels are widely utilized in diverse engineering applications worldwide.

2. Petrochemical Wells

HIC (Hydrogen Induced Cracking) resistant carbon steel emerges as a crucial solution in the oil and gas industry, especially for sour service applications. In environments where steel components frequently encounter hydrogen sulfide, there is a risk of hydrogen embrittlement and subsequent cracking over time. Dealing with this issue can be both costly and hazardous. However, by opting for HIC resistant carbon steel, these concerns can be mitigated effectively.

HIC resistant carbon steel represents an ultra-low carbon variant, meticulously designed to counteract such issues. Through desulphurization and dephosphorization processes, unwanted trace elements are eliminated, resulting in a pure and homogeneous steel boasting less than 0.2% carbon content. This specially crafted steel ensures superior resistance to hydrogen-induced cracking, offering a reliable and durable solution for sour service conditions in the oil and gas sector. Choosing HIC resistant carbon steel presents an opportunity to enhance safety, reduce expenses, and maintain operational efficiency in critical applications.

3. Shipbuilding

Carbon steel, including flat-rolled sheets of low-carbon steel and high formability mild steel, plays a vital role in crafting lightweight and highly durable constructions. In the marine industry, carbon steel finds extensive use in deck facilities across ships of different sizes, complementing the heavier and corrosion-resistant hull plating, which often contains a higher concentration of manganese.

The construction of ship superstructures involves a combination of various steel grades, with low and mild carbon steels forming the foundational layers for harder steel cladding. Steels with manganese concentrations as high as 1.65% are commonly utilized to produce robust steel plates, which are further surface treated to withstand a wide range of corrosive substances. These steel products become the backbone of hulls and superstructures, serving in the construction of container ships and passenger liners alike. Embracing the versatility and strength of carbon steel ensures the creation of maritime structures that exhibit excellent resilience and performance against challenging marine conditions.

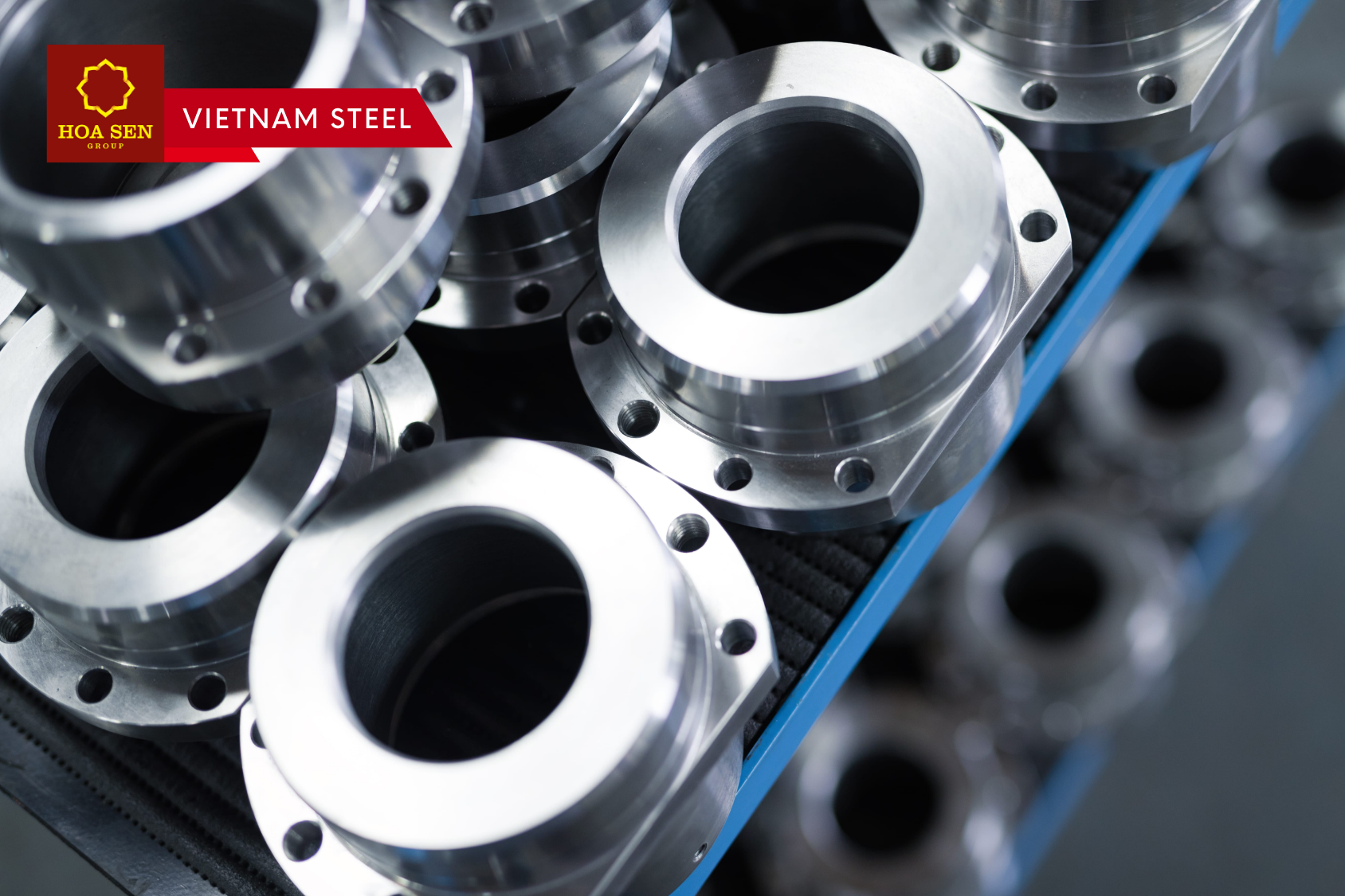

4. Pipeworks And Pressure Vessels

The gas and petrochemical industries stand out as major consumers of raw carbon steel materials, utilizing them to manufacture extensive networks of carbon steel pipework and pressure vessels, spanning millions of miles. In these applications, low-carbon steel emerges as a compelling choice, primarily due to its exceptional weldability, enabling the formation of intricate and rounded shapes. Moreover, low-carbon steel possesses valuable case hardening capabilities.

Case hardening, alternatively known as carburization, involves a treatment process that facilitates the migration of carbon to the steel's outer layer. This transformative process serves a crucial purpose: safeguarding the solid and ductile inner core while establishing a high-hardness crust on the vessel's or pipe's exterior. This hardened layer serves as a robust defense against a wide range of weathering factors, enhancing the longevity and reliability of these crucial gas and petrochemical industry components. Embracing low-carbon steel and its case hardening properties allows for the creation of durable and resilient structures, crucial for the success of gas and petrochemical operations.

Read More: What is Galvanized Steel? The Galvanized Steel Manufacturing Process

Vietnam Steel by Hoa Sen Group